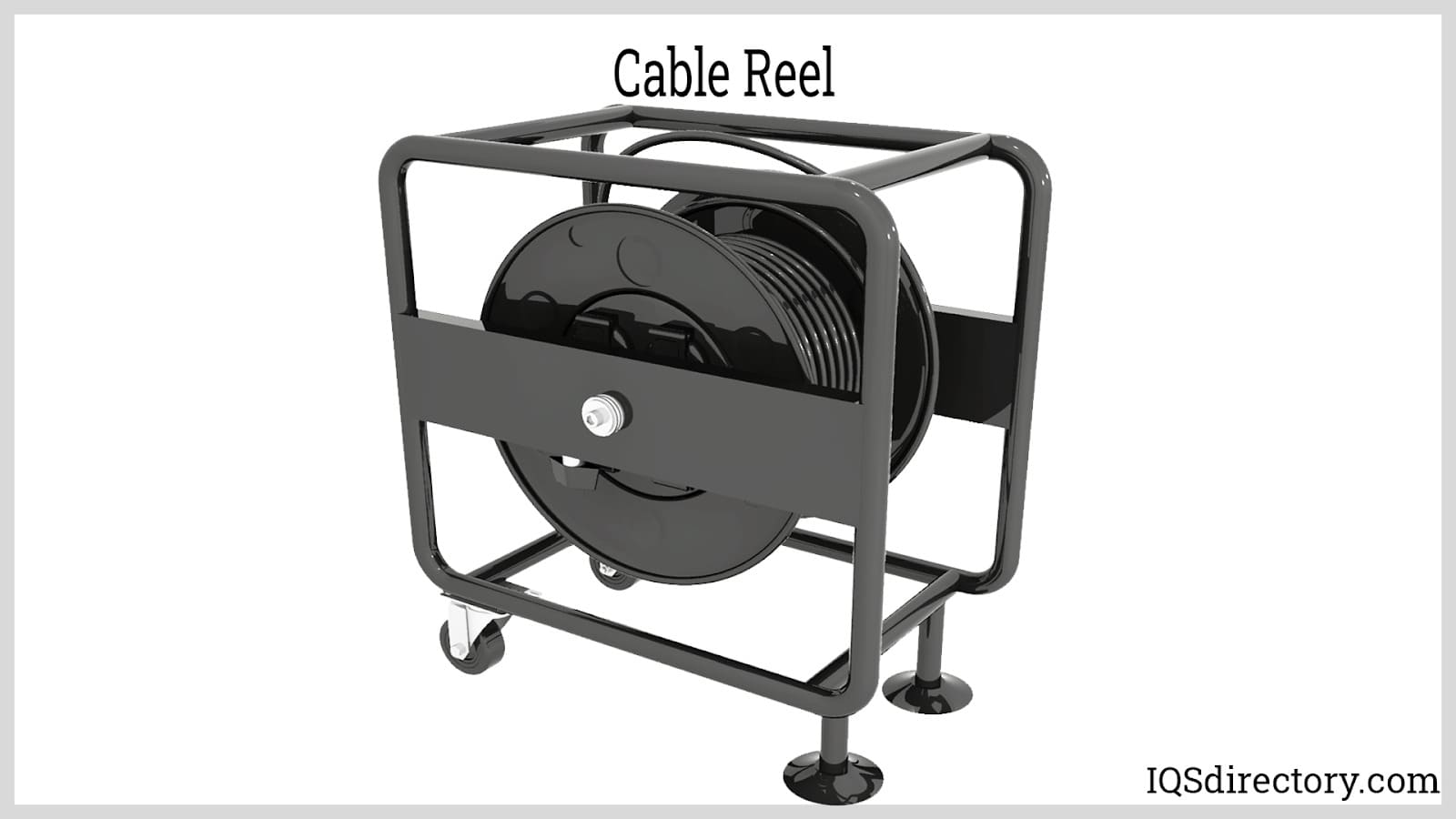

A cable reel is a spool-like, round item that is fashioned like a drum and used to transport different electrical wires. Electric cables, fiber optic cables, and other wire products are transported using cable reels, sometimes called drums. Cable reels are used for storing, unwinding, winding, and holding conductive cable or lifting cable. Electric cable reels have contacts that maintain electricity as they are being wound. Read More…

Hannay Reels is a leading manufacturer of hose and cable reels for OEM and aftermarket applications, offering thousands of standard models and a wide range of custom capabilities. Since 1933, Hannay has helped businesses in a variety of industries improve productivity, efficiency, and safety with consistent quality and outstanding customer service.

We are Unique Hosereels, a leading company in the manufacturing and distribution of hose reels, tank manifold systems, and valves. Our commitment to quality, innovation, and customer service has earned us a reputation as a trusted provider of reliable and durable products worldwide.

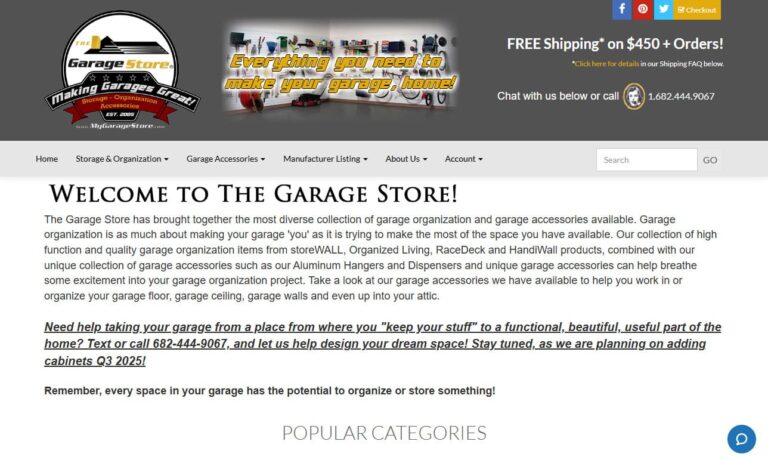

At Garage Store LLC, we take pride in helping customers transform their workspaces with hose reel solutions that deliver durability, organization, and long-term performance. We draw from years of hands-on experience to supply hose reels that support everything from small personal garages to demanding commercial environments, giving our customers the confidence that their air, water, and specialty ...

At Kent Rubber Supply Co., we take pride in delivering reliable hose reel solutions that keep industries moving safely and efficiently. As a trusted partner in fluid and material handling, we have built our reputation on quality craftsmanship, responsive service, and technical expertise.

More Cable Reel Manufacturers

Cable Reels: Types, Applications, and Buying Guide

If you're searching for reliable cable management solutions, cable reels are a vital component across many industries. This comprehensive guide will help you understand the different types of cable reels, their applications, benefits, and key considerations when selecting a cable reel supplier. Whether you’re looking for heavy-duty industrial cable reels, portable reels for job sites, or specialized reels for fiber optic cable management, this resource covers all essential aspects to help you make an informed decision.

What is a Cable Reel?

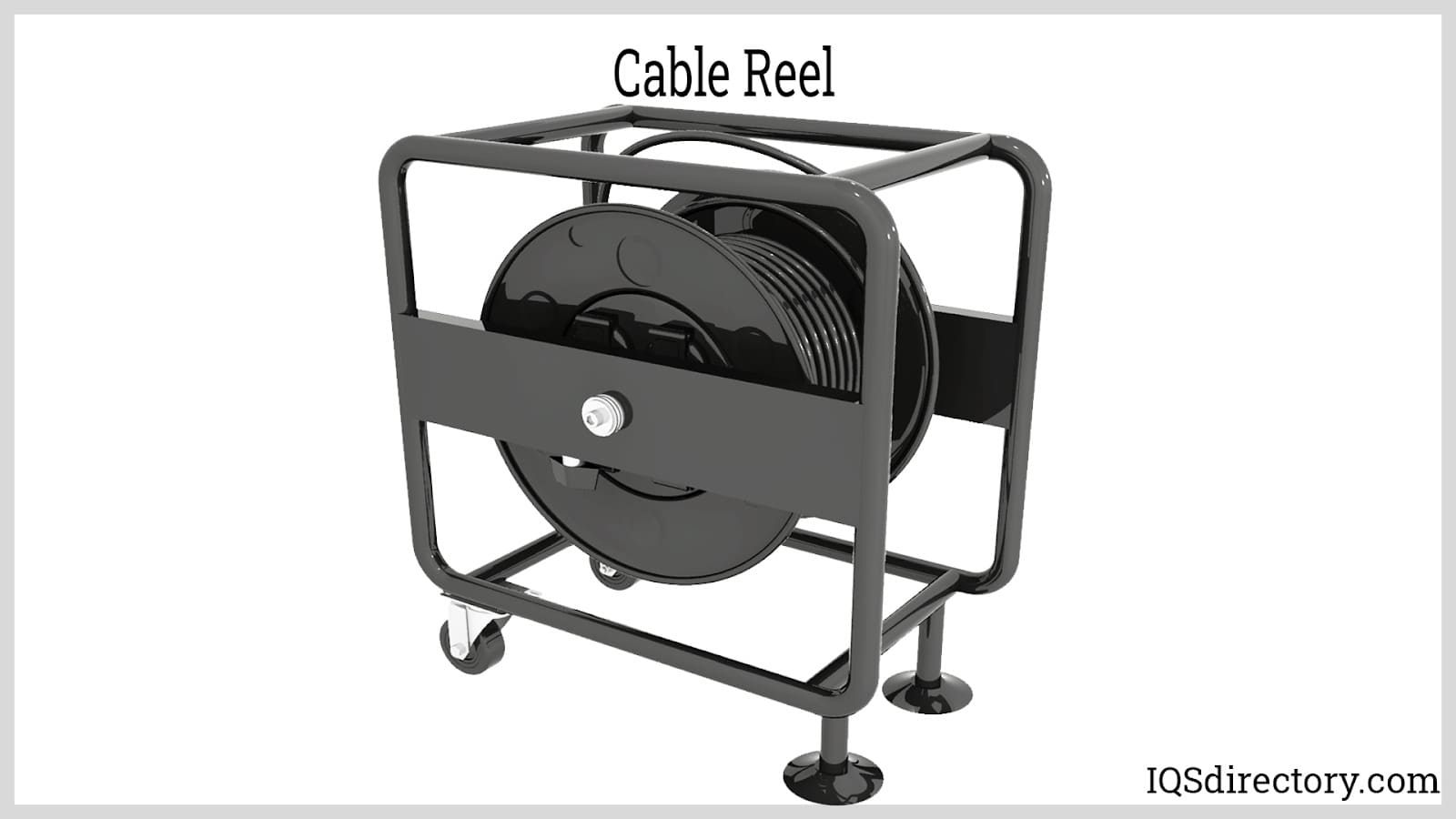

A cable reel—sometimes referred to as a cable drum or wire spool—is a cylindrical device used to carry, store, deploy, and retrieve electrical cables, wire ropes, hoses, or other flexible materials. They are essential in industries such as construction, telecommunications, utilities, mining, oil and gas, events, and manufacturing. Cable reels offer organized cable storage, protect cables from damage, and allow for safe and efficient handling during installation or transportation.

Types of Cable Reels

Steel Cable Reel

Steel cable reels are engineered for demanding industrial environments and are prized for their exceptional durability, longevity, and load-bearing capacity. While collapsible steel drums are available, most applications favor permanent welded steel drums for added strength and rigidity. These reels are often used for transporting and storing heavy-duty cables, high-tension wires, armored cables, and even hydraulic hoses. Commonly found in electrical utility projects, power distribution, shipyards, and large-scale construction sites, steel cable reels can be custom-fabricated to accommodate a wide range of cable diameters and lengths.

Environmentally conscious manufacturers produce steel cable coils using sustainable processes, making them a greener alternative to some traditional options. Additionally, spring-loaded steel cable reels—often called spring retractable cable reels—feature various mounting options (wall, ceiling, floor, or mobile carts). These spring-driven mechanisms automatically retract the cable, making them an ideal choice for applications requiring quick deployment and retraction, such as counterbalance, recovery, or return operations.

Key Advantages of Steel Cable Reels

- Superior strength and impact resistance

- Ideal for long-term outdoor and industrial use

- Supports heavier and bulkier cables

- Reusable and recyclable construction

- Customizable dimensions and mounting options

Wooden Cable Reels

Wooden cable reels are a traditional and cost-effective solution for winding, transporting, and deploying a variety of cables, wires, ropes, and other flexible materials. Typically constructed from durable hardwoods such as pine or plywood, these reels are widely used in electrical distribution, telecommunications, and temporary event setups. They are available in a range of traverse lengths and flange sizes, making them adaptable for different cable types and project requirements.

The manufacturing process of wooden reels involves several precise steps:

- Flange Creation: The round end sections (flanges) are formed by joining timber layers perpendicularly to ensure strength and stability.

- Shaping and Finishing: The flanges are cut into perfect circles using a bandsaw and then smoothed along the edges for a uniform fit.

- Customization: Flanges are tailored to user specifications, including the number and diameter of bolt holes, arbor holes, and start holes, as well as hole angles.

- Core Construction: The core, or drum, is built from machined staves—curved timber boards that form a circular cylinder when assembled.

- Assembly: Flanges and staves are bolted together to create a sturdy, reliable reel structure.

Wooden reels can be custom-treated for moisture resistance, making them suitable for both indoor and outdoor cable handling. Their renewable material composition also makes them a sustainable choice for many buyers.

Main Benefits of Wooden Cable Reels

- Cost-effective and widely available

- Customizable for various cable sizes and project needs

- Lightweight compared to steel alternatives

- Environmentally friendly and recyclable materials

- Easy to repair or repurpose after initial use

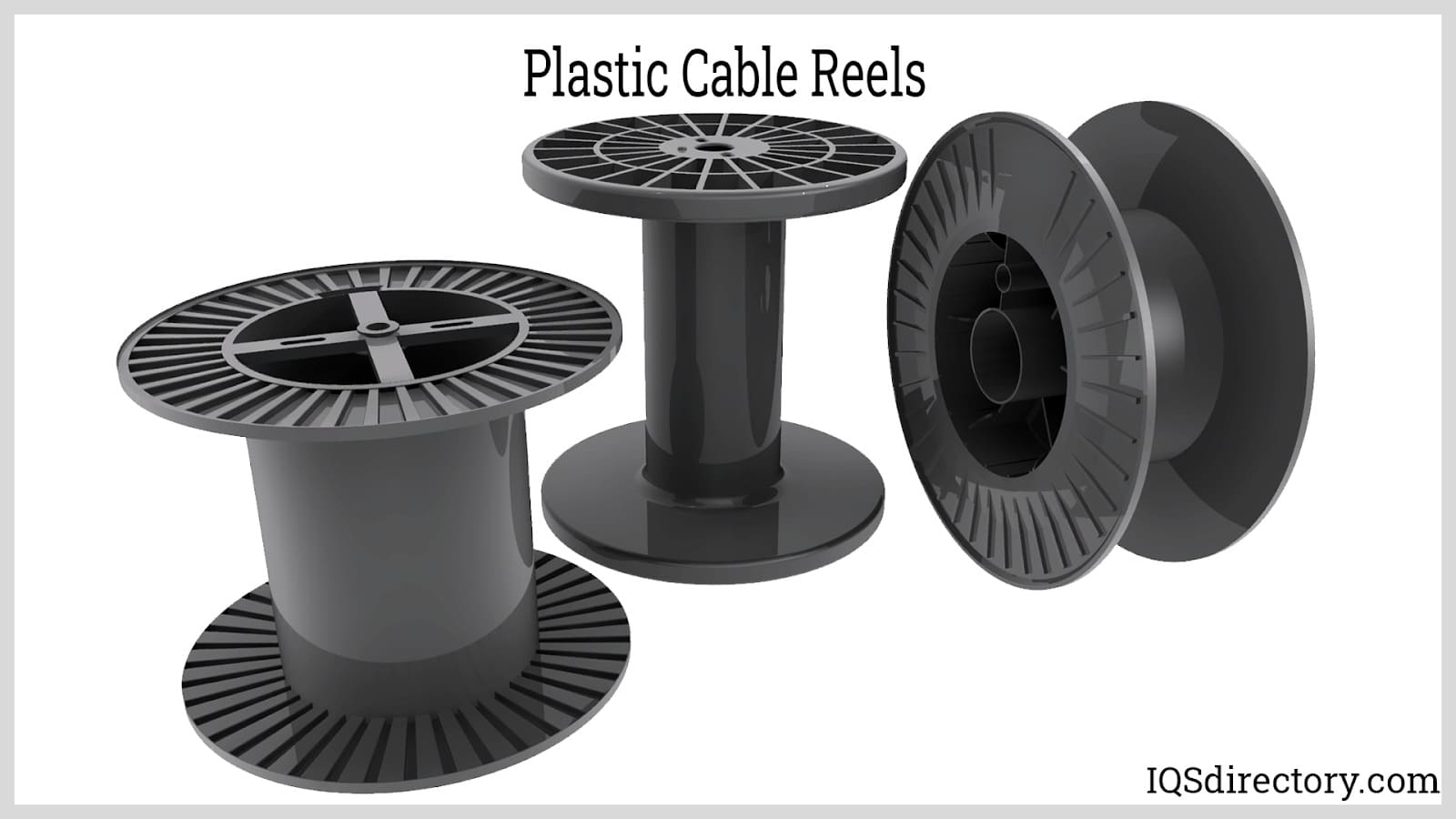

Plastic Cable Reels

Plastic cable reels, sometimes called polymer or composite reels, provide a lightweight, corrosion-resistant, and recyclable packaging solution for manufacturers and installers of monofilament, insulated wire, ribbon, tape, and electrical cables. These reels are commonly used in the electrical, medical, data communications, and consumer goods industries, where cleanliness, hygiene, and ease of handling are priorities.

Plastic cable reels are available in a variety of flange diameters, typically ranging from 6" to 24", but they can also be custom-molded or even 3D printed for specialized applications. Their reduced weight makes them ideal for portable cable management, shipping, and storage. Additionally, plastic reels meet stringent sanitation standards, making them suitable for medical device cables and laboratory environments.

Advantages of Plastic Cable Reels

- Lightweight for easy transportation and handling

- Fully recyclable and environmentally friendly

- Resistant to moisture, chemicals, and corrosion

- Customizable shapes and sizes, including 3D-printed designs

- Meets hygiene standards for specialized environments

Motorized Cable Reels

Motorized cable reels—also known as motor-driven cable reels, powered cable reels, or automatic retractable cable reels—are engineered for dynamic environments where cables must be deployed and retracted repeatedly in sync with moving machinery or vehicles. These reels are often employed in applications such as gantry cranes, overhead cranes, mobile platforms, mining equipment, wastewater treatment plants, and automated production lines.

Motorized cable reels typically integrate a drive unit (electric, hydraulic, or pneumatic motor), slip ring assembly for continuous power/data transmission, and a robust reel body. This configuration ensures cables are stored safely and tensioned properly, preventing slack, tangling, or damage during operation. They can accommodate a wide variety of cable types, including power cables, control cables, and fiber optic cables.

Some alternative names for these reels include motorized hose reels, electric hose reels, and even air hose reels, depending on the substance being managed. Their versatility makes them an essential component in industrial automation and mobile machinery operations.

Why Choose Motorized Cable Reels?

- Automated cable management for improved efficiency and safety

- Supports continuous energy and data transmission during movement

- Reduces cable wear, tangling, and operator fatigue

- Ideal for high-cycle and heavy-duty industrial environments

- Available with custom controls and integration options

Applications of Cable Reels

Cable reels play a critical role in a wide variety of industries and settings by ensuring safe, organized, and efficient cable management. Their applications include:

- Construction Sites: For on-site cable installation, cable reels enable efficient deployment and retraction of power cables, extension cords, welding leads, and more. They simplify cable handling, reduce tripping hazards, and protect cables from abrasion or crushing.

- Broadcast and Events: In live events, theaters, and broadcast production, portable cable reels are used for managing audio, video, and power cables. Rapid setup and teardown are essential in these scenarios.

- Telecommunications and Data Centers: Cable reels store and deploy fiber optic cables, Ethernet cables, and structured wiring, supporting high-speed data transmission and easy cable routing in complex installations.

- Industrial Automation: Motorized and spring-retractable cable reels are crucial for supplying power and control signals to moving machinery, such as cranes, hoists, conveyor systems, and automated guided vehicles (AGVs).

- Utility and Power Distribution: Utility crews rely on heavy-duty steel and wooden cable drums for handling high-voltage power lines, underground cables, and temporary power setups during maintenance or emergency repairs.

- Mining and Oil & Gas: Rugged cable reels are essential for powering and controlling drilling equipment, pumps, and mobile lighting systems in harsh environments.

- Vehicle Recovery and Off-Road: Vehicles, especially off-road trucks and emergency vehicles, use cable reels for winching and recovery operations, making them indispensable in challenging terrain.

- Fiber Optic Networks: Specialized steel reels are designed for storing and transporting fiber optic cables, which are delicate and require careful handling to maintain signal integrity.

Common Use Cases for Cable Reels

- Temporary or permanent power distribution in construction and industrial sites

- Audio/video cable management for concerts, broadcasts, and theater productions

- Safe deployment of communication and control cables in automation systems

- Winching, towing, and vehicle recovery operations

- Organized storage of extension cords, hoses, and specialty cables

- Supporting mobile equipment in mining, marine, and rail industries

- Medical and laboratory cable handling for equipment and instrumentation

Benefits of Using Cable Reels

Investing in quality cable reels provides numerous advantages for cable management, safety, and operational efficiency:

- Enhanced Safety: Prevents tripping hazards and cable damage by keeping cables organized and off the ground.

- Longer Cable Lifespan: Protects cables from excessive bending, abrasion, and environmental exposure.

- Improved Productivity: Enables quick deployment, retrieval, and storage, reducing downtime and labor costs.

- Space Optimization: Compactly stores cables when not in use, freeing up valuable workspace.

- Customizable Solutions: Wide range of materials, sizes, and mounting options to fit every application.

- Compliance: Supports regulatory and safety standards for cable handling in industrial environments.

How to Choose the Right Cable Reel?

Choosing the best cable reel for your specific needs depends on several critical factors. Here are key questions to ask and steps to follow during your selection process:

- What type of cable or hose will be managed? Consider diameter, length, weight, and flexibility.

- Where will the cable reel be used? Determine if your application is indoors, outdoors, or in a corrosive or hazardous environment.

- What is the required load capacity? Heavier cables may require steel or reinforced reels, while lighter tasks can use plastic or wooden reels.

- Do you need manual, spring-loaded, or motorized retraction? High-cycle or automated operations may benefit from motor-driven reels for increased efficiency and safety.

- What mounting options are necessary? Options include wall, ceiling, floor, cart, or vehicle mounts.

- Are there specific standards or certifications required? Industries such as medical, mining, or explosive environments may require specialized reels with compliance certifications.

- Is customization needed? Many suppliers offer custom fabrication to match unique cable sizes or operational requirements.

Action prompt: Need help specifying a cable reel for your project? Contact our cable reel experts or request a custom quote today.

Comparing Cable Reel Materials: Steel vs. Wood vs. Plastic

| Material | Strength/Durability | Weight | Corrosion Resistance | Cost | Common Applications |

|---|---|---|---|---|---|

| Steel | High | Heavy | Excellent (with coating) | Higher | Industrial, Utility, Mining, Marine |

| Wood | Moderate | Moderate | Limited | Lower | Electrical Distribution, Temporary Installations |

| Plastic | Light-Moderate | Light | Excellent | Variable | Medical, Data, Consumer, Portable Use |

Frequently Asked Questions About Cable Reels

What is the difference between a cable reel and a hose reel?

While both are cylindrical devices used for winding and unwinding flexible materials, cable reels are specifically designed for electrical cables, data cables, or wire ropes, while hose reels are intended for fluid-carrying hoses such as air, water, or hydraulic lines. They often differ in material construction, core design, and retraction mechanisms.

How do I select the correct size cable reel?

Consider the total length and diameter of the cable, the bend radius required, and the maximum weight the reel must support. Most manufacturers provide cable reel sizing calculators or specification charts to help you choose the optimal size for your application.

Can cable reels be customized for unique projects?

Yes, many cable reel suppliers offer custom solutions including special flange diameters, core dimensions, mounting brackets, retraction speeds, and color options. Customization ensures the cable reel integrates seamlessly with your workflow and meets all operational requirements.

Are there safety standards for cable reels?

Industrial cable reels should adhere to relevant safety and operational standards such as OSHA requirements, UL or CE certifications, and IEC guidelines. Always confirm your application’s needs with your supplier to ensure compliance.

How can I maintain and extend the life of my cable reels?

Regular inspection, cleaning, lubrication (for metal components), and proper storage are essential. Protect reels from harsh environments when not in use, and avoid overloading beyond rated capacities. For spring or motorized reels, follow manufacturer maintenance schedules.

Choosing the Proper Cable Reel Supplier

Finding the right cable reel manufacturer or cable reel supplier is crucial for obtaining reliable, long-lasting products tailored to your industry’s specific requirements. Here are some steps and decision factors to consider:

- Experience and Reputation: Research each supplier’s history, expertise, and customer reviews. A proven track record in your industry is a strong indicator of reliability.

- Product Range: Ensure the supplier offers a broad selection of cable reel types, including steel, wood, plastic, and motorized options, as well as customization capabilities.

- Quality Standards: Look for manufacturers who comply with ISO, CE, or UL certifications and offer warranties on their products.

- Lead Times and Delivery: Evaluate production capacity, lead times, and shipping options to ensure timely delivery for your project.

- Customer Support: Choose suppliers who provide technical support, installation guidance, and after-sales service.

- Pricing and Value: Compare quotes from multiple suppliers, balancing cost with quality, features, and after-sales benefits.

Our directory makes it easy to compare reputable cable reel suppliers. Each company profile highlights areas of expertise, product capabilities, and direct contact options for requesting information or a quote. Use our website previewer to quickly review each supplier’s focus, and our RFQ form to contact multiple companies simultaneously—saving you time and ensuring you get the best solution for your cable management needs.

Ready to Find the Best Cable Reel for Your Application?

Whether you’re sourcing standard or custom cable reels, optimizing cable storage in your facility, or upgrading to automated cable management systems, we’re here to help. Contact our team for expert guidance, browse our supplier directory, or request a quote now to get started on your next project.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches